I recently had the need to cut polystyrene sheets for the high altitude balloon payload enclosure. It is almost impossible cut polystyrene properly with a blade. If you do it you will make a mess. You need to use the right tool for the job.

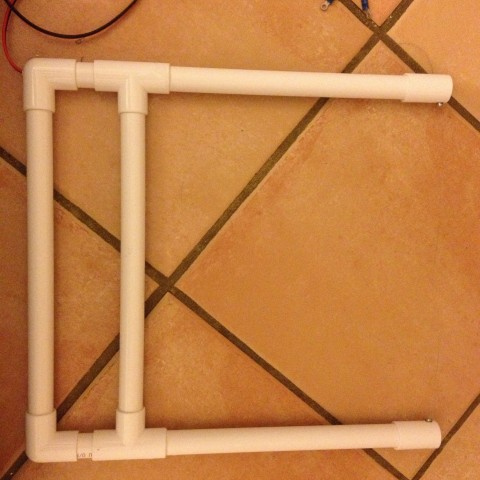

I purchased some PVC pipe, some joints, some glue and some resistance wire (nichrome). I built the cutter so that it can be used by hand or clipped onto a holder to create a crude bench cutter.

I wired the nichrome up to some 2 core DC cable. The only problem I found with it during testing was it wasn’t easy to turn off heated wire if I needed to remove the cutter without further cutting. I think I shall include a push switch or toggle so I can easily power it off.

As a power supply I used a bench supply which I slowly wound up the voltage until I got a reasonable heat on the wire. I found around 12v was perfect. I had about 1.5A of current reading. I’ve not done the maths to see what the wire will take before melting but it seemed to be fine.

The only thing I am going to change is the mounting arrangement for the wire. I wanted to use M3 eye bolts but I haven’t managed to source any yet. This will allow me to control the tension on the wire which is difficult to manage with bolts alone.

The mounting plate I plan to build is quite simple and shouldn’t take too long to build.