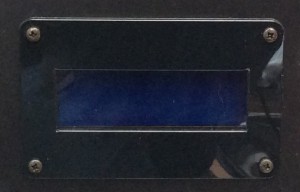

Whilst building the Thunderbolt Monitor I wanted to provide a clean, professional look to the LCD cutout. It is hard to cut out a very clean hole with crisp corners and straight edges from aluminium without a lot of patience and a lot of filing.

I designed a plastic bezel and glass using CAD and had a number professionally laser cut. The plastic is high gloss black.

I am now making them available for purchase with all the spacers and mounting screws you require to mount a 4×20 LCD to a panel.

The bezel and glass come with the plastic protective covering still attached to prevent scratches until you’re ready to install it.

They cost £4 with £1 delivery to the UK and £3 delivery to the rest of the world and are now available in the shop.