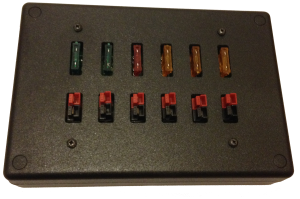

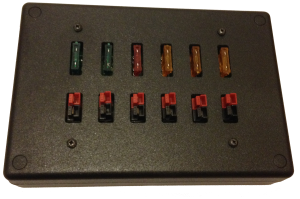

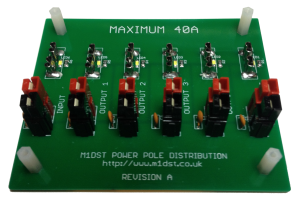

I’ve been working on a small Powerpole distribution unit to compliment the bigger brother already available. It is now possible to purchase it from http://www.m1dst.co.uk/shop/.

I’ve been working on a small Powerpole distribution unit to compliment the bigger brother already available. It is now possible to purchase it from http://www.m1dst.co.uk/shop/.

It is also available with the common XT60 connector.

I’ve been working on a small Powerpole distribution unit to compliment the bigger brother already available. It is now possible to purchase it from http://www.m1dst.co.uk/shop/.

I’ve been working on a small Powerpole distribution unit to compliment the bigger brother already available. It is now possible to purchase it from http://www.m1dst.co.uk/shop/.

It is also available with the common XT60 connector.

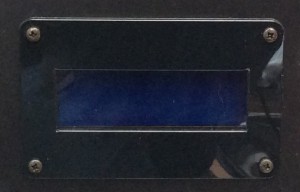

Whilst building the Thunderbolt Monitor I wanted to provide a clean, professional look to the LCD cutout. It is hard to cut out a very clean hole with crisp corners and straight edges from aluminium without a lot of patience and a lot of filing.

I designed a plastic bezel and glass using CAD and had a number professionally laser cut. The plastic is high gloss black.

I am now making them available for purchase with all the spacers and mounting screws you require to mount a 4×20 LCD to a panel.

The bezel and glass come with the plastic protective covering still attached to prevent scratches until you’re ready to install it.

They cost £4 with £1 delivery to the UK and £3 delivery to the rest of the world and are now available in the shop.

I ran a third batch of the monitor and most are now gone. The are just a few still available in the shop. If you want one, please be quick.

I’ve been selling these distribution boxes all over the world and have been really pleased with the interest. I decided I would build another one for myself for use with the 48v SSPAs I have. I uprated the resistors and the capacitors. Here is the finished result.

Last week I installed a bandpass filter which I purchased from http://www.fmbroadcastparts.com/ into my 500w SSPA.

Its design is optimised for use with 600W & 800W & 1KW pallet amplifiers and can be mounted on the same heat sink as the pallet. I bolted mine on the front panel of the linear which is made of aluminium.

Only first class RF Microwave components are used on a silver plated Rogers Teflon PCB with silver plated copper inductors and Teflon PCB capacitors are used to minimize internal loss and best possible harmonic suppression.

Although available in 2 versions, coaxial connections or N female connectors, I chose to use the coaxial connection version.

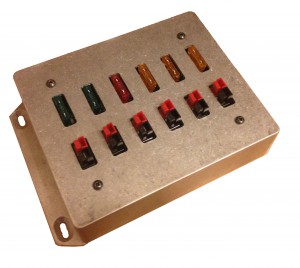

I had a small run of aluminium boxes machined at the same time as the ABS enclosures. I really like them but they cost quite a bit more to produce.

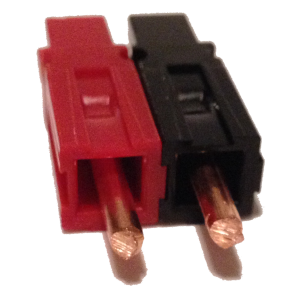

A DIY DC distribution system based around the popular Anderson Powerpole connectors.

A DIY DC distribution system based around the popular Anderson Powerpole connectors.

Ideal for amateur radio applications or even RC enthusiasts who wish to connect several batteries in parallel to charge. The kit contains everything you need to build the project including a professionally machined ABS enclosure.

You could mount one if these in the car, under your shack bench or include it in your “go” bag for portable use.

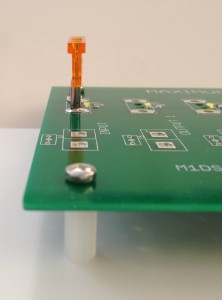

There is a single input fuse which if removed will isolate all other items connected from the power.

You will receive a PCB and all of the components required to populate it. You will receive a 4 page document explaining how to construct it. There is nothing complicated with building this and as long as you have a reasonably powerful soldering iron you should be fine.

You will also receive an ABS enclosure and standoffs. The enclosure has been commercially machined so there is no work required from you.

£35 + postage

The second batch of monitor kits have completely sold out again. Please email me to express interest and I will then be able to gauge when/if another production run is required.

Glad there are so many out in the field now.

After having received the prototype enclosure back and being so pleased with it I thought getting the rest cut would be a doddle. This didn’t turn out to be the case. Having had the order accepted from the laser cutters and shipping off the boxes I later had them returned with an apology that they were unable to cut them after attempts to reproduce them had failed. They found that the ABS was melting and catching fire and releasing Cyanide gas.

That meant that milling was the only viable option. I found a number of local suppliers and contacted them for quotes. Most claimed that no job was too small… Out of the 5 I contacted, one returned my email. The quoted a crazy price per box (£20) and couldn’t start for 6 weeks. Somehow I don’t think they wanted the work.

I then found a number of suppliers on eBay. I contacted a number of them and got 2 responses. Having had a friendly telephone conversation with one of them and a reasonable quote I have shipped the boxes off to get machined. They are very confident that they can machine them to the quality I require.

I am getting a large number of enquiries to purchase these and most people want more than one. I’ll keep you all posted on progress. I’m looking forward to getting this project finished once and for all.

I will also now be supplying a 40a fuse with each kit as the main input fuse.

I have received the prototype Powerpole Distribution enclosure back from the laser cutters and am very pleased with the results so I’ve sent off a large number of lids to be cut.

I’m hoping the I will receive them back in about a week or so at which point I will add the kit to the store. There will be fully built versions available too for those of you without the tools or time.

I’ve recently received interest in just the bare PCBs which is an interesting idea. I have invested heavily in the PCBs, components, Powerpoles and the laser cut enclosure which I need to clear first. I’ve had to purchase in bulk to make the kits cheap. If once the first batch of kits sell out there is enough interest in bare boards I may get another run of boards produced. The question I have is why you want to go to all the effort of sourcing the parts and cutting your own boxes?

I’ve learnt quite a bit whilst taking the idea and turning it into reality. I also now have contacts to make beautiful PCBs in large quantities and a local(ish) company with laser cutting skills. I’ve even had to learn basic CAD skills to ensure the job got done properly. All of the skills gained will come in handy for the next project for which I am already writing code and collecting components for a prototype. More on that soon.

An error has occured.